Comparison of pile drivers

Related Articles

Share This Article

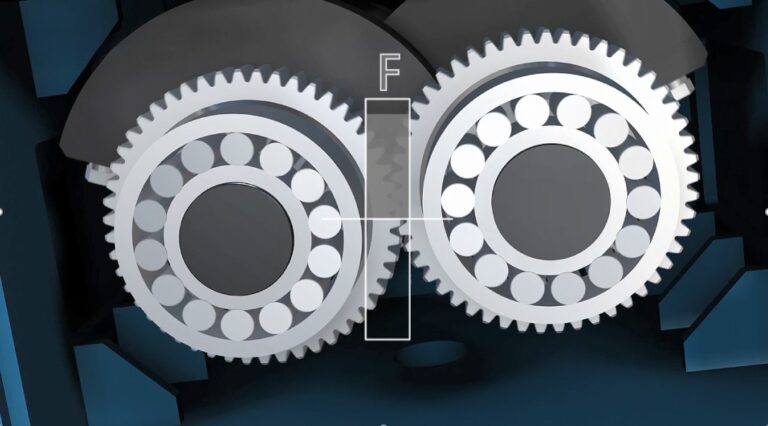

Principle of vibratory hammer

The working principle of vibro hammer is to generate up and down vibration through the relative motion of two eccentric gears, so as to separate the affected object from the surrounding soil layer, reduce frictional resistance, and achieve the purpose of piling and pulling.

Sheet Pile (Larssen Pile)

Steel sheet pile has been produced in Europe since the early 20th century. The engineer who invented this steel sheet pile is named Larssen, that is why we call it Larssen pile.

The steel sheet pile is driven into the soil layer by the pile driver. Then necessary support or tension anchor is set to resist the earth pressure and water pressure and maintain the stability of the surrounding stratum.

It is fast, efficient and environmental by using steel sheet piles as retaining construction. It was widely applied in the restoration project after Kanto earthquake in 1923.

Now steel sheet pile is widely used as revetment, retaining walls and embankment revetments.

Steel sheet pile can be divided into linear type, Z type, U type, H type and cap type according to lock openings.

There are many construction equipment for steel sheet pile, which can be divided into the following types according to piling methods: Vibratory hammer, Impact piling hammer, Silent Piler.

All kind Piling Equipment

Vibratory hammer

Include Crane Mounted hydraulic vibratory hammer, excavator mounted vibratory hammer, electric vibratory hammer

Advantages of vibratory hammer:

Vibratory hammer can not only drive pile but also extract pile. It is applicable for temporary protection works.

The vibratory hammer generates high-frequency vibration through the rotation of the eccentric blocks. The eccentric blocks appear in pairs, rotate in opposite direction, the transverse centrifugal forces counteract each other, and the vertical centrifugal forces are superimposed. High-frequency vibration makes the soil liquefy instantly, and then the pile is plugged into the soil through self-weight and downward pressure.

Crane Mounted Hydraulic vibratory hammer

It is usually lifted by the crane, and the hydraulic power is provided by a special power station. This is applicable for large construction projects with luge and heavy piles.

Excavator Mounted Vibratory Hammer

It is installed on the excavator and uses the excavator power which is flexible and convenient for construction.

Side Grip Excavator Vibratory Hammer

Usually, the pile driver exerts impact force on the top of the pile, which has high request for construction space. The side grip vibro hammer solves this problem. It can clamp any part of the pile.

The vertical grip excavator vibratory hammer can only move the pile vertically after clamping it. The side grip excavator vibratory hammer can over turn and translate the pile. The construction convenience is very prominent.

Electric Vibratory Hammer

The power is provided by the generator. The hammer is connected to control cabinet. The low-frequency vibration produces an centrifugal force with large amplitude. It is applicable to general working conditions.

Impact Piling Hammer

The pile is poured into the stratum by impact force. Impact hammer is divided into drop hammer, steam hammer, diesel hammer, and hydraulic hammer according to the power source.

Drop Hammer

The winch lifts heavy objects and then falls freely along the guide frame to produce impact force.

Steam Hammer

The hammer head is driven to rise by steam, and then falls along the guide rod to produce impact force.

Diesel Hammer

The power is generated by a two-stroke diesel engine. The guide rod connects to the piston and the hammer head to output the impact force.

Silent Piler

It uses the principle of reaction force. It obtains the reaction force by clamping several piles (completed piles) which have been pressed underground. Then uses the hydraulic static load to press the next pile into the ground.

Silent piler without any vibration and noise during construction, but it is much more expensive than other pile drivers.

How to Choose Sheet Pile Driver

The following conditions should be considered when selects construction equipments.

1. Project scale: quantity, size and shape of driven (extract) steel sheet piles.

2. Soil condition: needs to consider the soil condition for driving or extracting steel sheet piles.

3. Operating environment: the selected machinery needs to meet the requirements of noise, vibration and other public hazards and also considers on site conditions such as traffic, terrain and so on.

| Hammer Type | Vibratory hammer | Impact hammer | Silent Piler | |||||

| Electric hammer | Hydraulic hammer | Excavator side grip hammer | Excavator hammer | Diesel hammer | Drop hammer | Steam hammer | ||

| Pile Type | All | All | All | All | Most | All | Most | All |

| Pile Length | All | All | All | All | All | limited | All | All |

| Soft silt | OK | OK | OK | OK | No | OK | OK | could |

| Silt, clay | OK | OK | OK | OK | OK | OK | OK | OK |

| Sand layer | OK | OK | OK | OK | OK | No | OK | OK |

| Hard soil layer | No | No | No | No | OK | No | OK | No |

| Auxiliary equipment | Large | Large | No | No | Large | Simple | Large | Large |

| Vibration | Large | Large | Large | Large | Large | Small | Large | No |

| Noise level | High | Medium | Medium | Medium | High | High | High | None |

| Speed | Fast | Fast | Fast | Fast | Fast | Slow | Fast | Medium |

| Cost | Fare | Fare | Fare | Fare | High | Low | High | High |

| Project scale | Large | Large | All | All | Large | Simple | Large | Large |