excavator vibratory hammer pile driver

Advantage of excavator vibratory hammer

Piling and extracting

Excavator vibratory hammer can not only drive pile but also extract pile. It is applicable for temporary protection works.

No need auxiliary equipment

Excavator mounted vibratory hammer uses the power from excavator, no need any extra power station.

Flexible and convenient

Excavator mounted vibratory hammer can drive a pile within 5 minutes, and quickly move to next position.

It can pick pile by itself, only few workers demand.

| Data/Model | V150 | V250 | V300 | V350 | V400 | V450 | V500 | V550 | V600 |

| Max Centrifugal Force (KN) | 287 | 333 | 385 | 431 | 461 | 501 | 534 | 574 | 607 |

| Excavator Weight (T) | 10-15 | 20-25 | 25-30 | 30-35 | 35-40 | 40-45 | 45-50 | 50-60 | 60-65 |

More than 10 years experience in piling equipment.

Professional R&D team and have obtained 46 inventions and patents.

Certificated by ISO9001, ISO14001 international standard quality management system and CE.

First manufacturer of side grip vibro hammer in China.

Exported to the United States, Russia, Philippines, India, and more than 60 countries and areas.

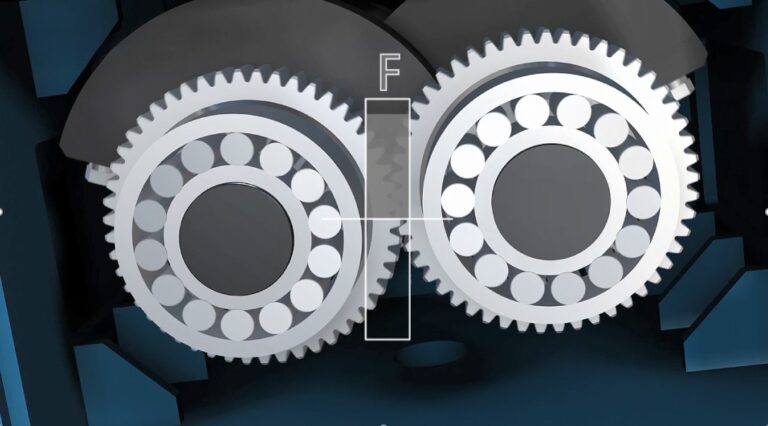

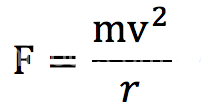

Principle of vibratory hammer pile driver

The centrifugal force is produced by eccentric block vibration. The eccentric blocks appear in pairs, opposite rotation direction, the transverse centrifugal forces counteract each other, and the vertical centrifugal forces are superimposed.

High frequency vibration makes the soil liquefy instantly, and then the pile been inserted into the soil through hammer weight or excavator pressure.

1. No height limit

The top grip vibratory hammer clamps the pile from the top, so the pile length can not exceed the height of the excavator’s boom. However the side grip type clamps the side of the pile without considering the pile length.

So side grip vibratory hammer can work in limited space, like workshops, underbridges.

2. More flexible

Side grip vibratory hammer can turn 3-axis rotation, also move pile as flexible as an arm.

Top grip vibratory hammer can’t tilt the pile.

3. Safe

Top grip vibratory hammer clamps the upper end of pile, but the bottom is unbalanced shaking. Extra labour is necessary to hold and aim at the lock of each pile, but it causes potential danger.

Side grip type clamps the side of pile with more stable clamping force which is easy to pile precisely.

4. No need modify excavator

For installation of side grip vibratory hammer, you only change bucket to hammer.

However for top vibratory hammer, you need to modify prolonged boom and move the excavator counterweight backward.

Side grip vibratory hammer can save both cost and labour in modification.

Flexible

Working indoor

Working under bridge

Sheet pile driver

Sheet pile is called Larssen pile also, it’s widely used as revetment, retaining walls and embankment revetments.

The steel sheet pile is driven into the soil layer by the sheet pile driver. Then necessary support or tension anchor is set to resist the earth pressure and water pressure and maintain the stability of the surrounding stratum.

It is fast, efficient and environmental by using steel sheet piles as retaining construction.

There are many types of construction equipment for steel sheet pile. But the excavator pile driver is the mainstream, efficient and flexible one.