Vibratory hammer feature, components and application

Related Articles

1. Vibratory hammer application

With the rapid development of the construction industry in recent years, the pile foundation has gradually developed from wood piles to reinforced concrete piles or steel piles. There has also been a huge development in the construction methods and construction machinery of the foundation.

The vibratory hammer is widely used to drive and pull out various steel piles like sheet piles, tube, H beam, I beam piles and concrete piles.

It has the advantages of strong pouring force, good pile driving effect, sturdiness and durability, few failures, convenient use, and low noise

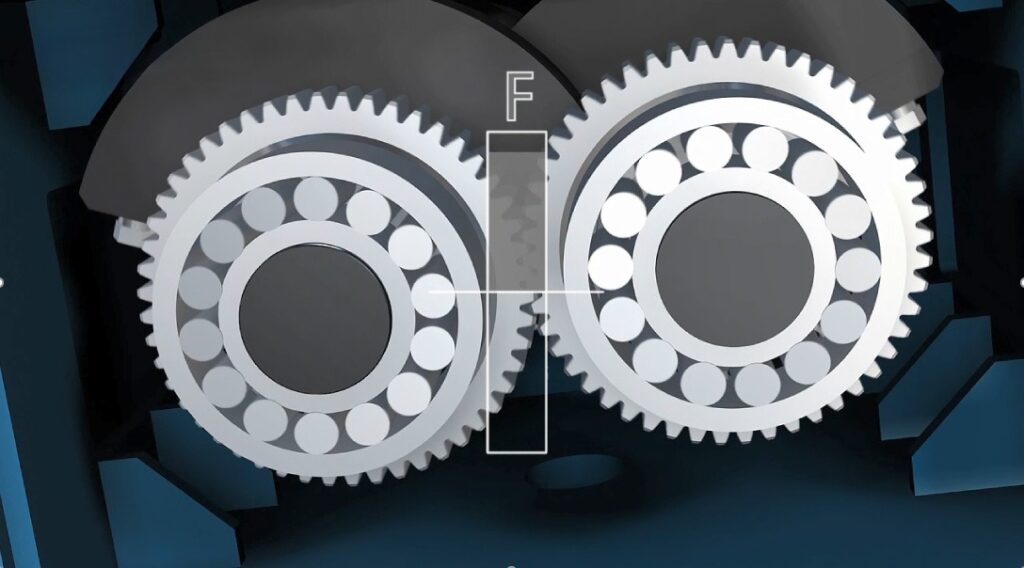

2. Principle of vibratory hammer

The working principle of vibro hammer is to generate up and down vibration through the relative motion of two eccentric gears, so as to separate the affected object from the surrounding soil layer, reduce frictional resistance, and achieve the purpose of piling and pulling.

3. Main components of vibratory hammer

- Rotation disc

- Gear box

- Vibration Reduction

- Frame

- Hydraulic motor

- Clamp

- Hydraulic oil system

- Control system

- Hanger and axis

3.1 Rotation disc

Rotation discThe latest gear built-in design to prevent dirt and impact,

replaceable gears run smoothly and are durable.

3.2 Gear box

The core component and power source of the machine. FAG bearing with excellent quality.

3.3 Vibration reduction frame

High-performance elastomers, stable quality, long use life.

3.4 Hydraulic motor

Original Europe imported hydraulic motor, efficient and high quality.

3.5 Clamp

Various types for all kinds of piles; powerful hydraulic cylinder, wear-

resistant jaw; strong casting body.

3.6Hydraulic oil system

Special functions and features designed for the

Excavator vibro hammer.

3.7 Control system

Electric control by handle, convenient operation, multifunctional integration, beautiful and practical. Easy to install and maintain.

3.8 Hanger and axis

Well-designed, strong and easy maintenance.

4. Feature of vibratory hammer

4.1 Environmentally friendly

The vibratory hammer is an environmentally friendly piing equipment. Compared with impact hammers and diesel hammers, high-frequency hydraulic vibrating hammers have less vibration and noise during construction, and do not disturb the people. It is very suitable for urban areas and places with large crowds. and construction in places with stricter restrictions on the surrounding area.

4.2 High effective

4.2 Generally speaking, the construction efficiency of high-frequency hydraulic vibratory hammer is ten times that of ordinary pile machinery. The speed of vibrating pile driving is generally 4-7 m/min. The special pile frame can be used together to shorten the pile setting time and improve the work efficiency.

4.3 Multifunctional

4.3 The vibratory hammer is multifunctional piling equipment. The high-frequency hydraulic vibratory hammer can not only pile and pull concrete prefabricated piles (PHC piles), various types of steel sheet, tube, H beam, and I beam piles, but also can be used as driving cast-in-place piles, thin-walled anti-seepage walls, surface compaction, and deep compaction projects.

Tube pile is a new type of piling process with great application and promotion prospects in the field of pile foundation. It is an economical, effective and environmentally friendly piling process to use high-frequency hydraulic vibratory hammer for the construction of tube piles. It is more efficient, more environmentally friendly and more energy-saving than the cast-in-place piles formed by the current rotary drilling rig.

4.4 Light and flexible

The vibratory hammer is a relatively light piling equipment. Compared with the static pile driver, under the same working conditions, the total working weight of the high-frequency hydraulic vibratory hammer is only one-twentieth of that of the static pile driver. It is very convenient for transportation.

4.5 wide range of geological conditions

The vibratory hammer is a type of piling equipment suitable for a wide range of geological conditions. High-frequency hydraulic vibratory hammers are divided into three series: conventional type, high-frequency type, and non-resonant type. According to geological conditions and engineering needs, high-frequency hydraulic vibratory hammers of different series and different excitation forces can be selected as construction machinery. The ability to penetrate the pebble layer, sand layer, construction waste and other geological layers is very strong, and it can adapt to any other geological conditions except that it cannot enter the rock.