Sheet pile driving method by vibratory hammer

Related Articles

Share This Article

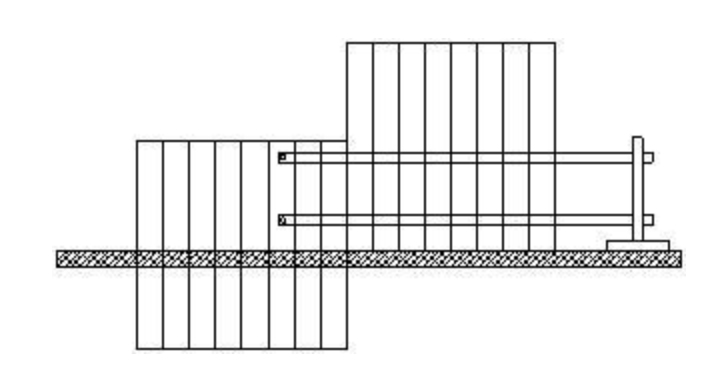

1. Screen piling

Insert 10~20 sheet piles into the soil to a certain depth, make the pile driver hammer back and forth, and drive the 12 piles at both ends to the required depth, and then drive the sheet piles in the middle part in sequence. This screen construction method can prevent the inclination and rotation of sheet piles, and is often used for enclosure structures that require closure.

Using this method can ensure good verticality, reduce the difficulties and loose piles that may be encountered in the pile driving, and can better control the length of the pile wall. Because the whole piles are positioned together, not all the piles are driven to the design elevation, which ensures that the local piles will not be driven to the design elevation, so as to avoid the overall effect of the destruction of the wall occurs. The disadvantage is that the construction speed is slower than that of the single-pile construction method and the pile frame is high.

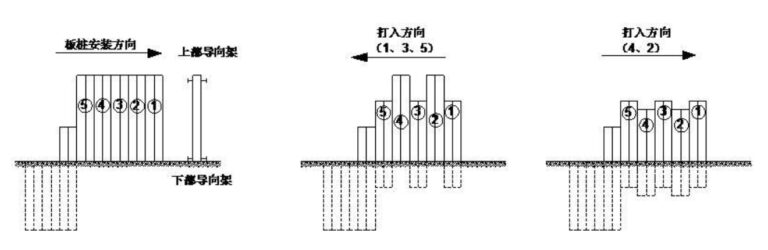

2. Staggered piling

For soils that are difficult to pile, use this method to carry out pile driving construction. Install the sheet piles between the guide frames, and then construct them in the following order: first, No. 1, No. 3, No. 5, and then No. 2 and No. 4. If under the circumstance of very dense sand, gravel, or rock, the No. 1, No. 3 and No. 5 pile tips can be reinforced. In this case, the tip-reinforced piles are always constructed first.

3. Combined pile wall piling

The composite pile wall is composed of main piles and intermediate auxiliary piles. The main pile forms include pipe piles, box piles, load-bearing piles, and other forms of piles. The key to using composite piles is to use a stable guide frame with sufficient rigidity. The main pile adopts the welding triangular guide plate to locate the guide frame. Guide plate dimensions take into account width deviations. The main pile should be driven straightly and vertically, or maintain the specified slope to ensure that it is parallel to other piles and maintains the specified clearance. The pile driving sequence of the main pile must ensure that the entire pile tip is evenly contacted with the compacted soil, instead of only one side. Therefore, piles must be driven in the following order 1, 5, 3, 6, 4, 7, 2, with big interval skip; or at least in the following order: 1, 3, 2, 5, 4, 7, 6, with small interval skip . In principle, all main piles must be driven to the design depth in sequence without interruption. The positioning and piling of the intermediate light piles will only be carried out after the normal completion.